Model originally uploaded to Thingiverse at https://www.thingiverse.com/thing:4975364.

New and improved version with two blower fans now available here: https://www.thingiverse.com/thing:4979221

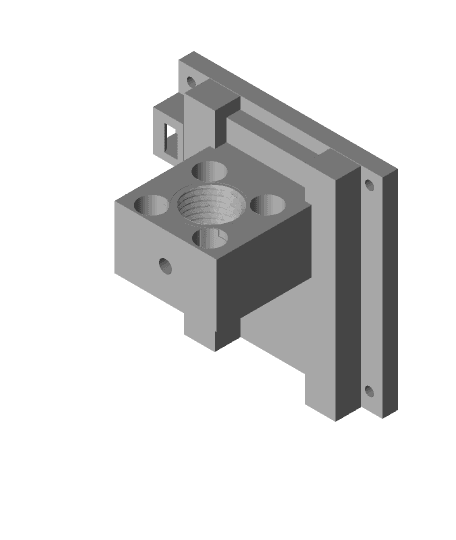

DescriptionThis is a completely new effector for the Flsun Q5 delta printer for mounting any v6 hotend that conforms to the E3D V6 standards using the grooved mount.

This includes the E3D V6 itself (tested), V6 clones (tested) and the newer Dragon (tested) and Dragonfly hotends (not tested) from Phaetus and sold through companies such as TriangleLab.

Additional mounts and components included for direct Phaetus Dragon hotend attachment (tested) (i.e. without the groove mount adapter), as well as a E3D Volcano hotend (tested).

This effector has been built from a blank sheet and has gone through several iterations to get to this point.

There are three major components:

The effector plateThis has been designed to take M3x5mm thread inserts (6 in total) to connect to the delta arms. As this is the part nearest the heat block and in contact with the heat sink, it needs to be printed in a heat tolerant filament. Testing has shown ABS and ASA are probably the minimum you will be able to print it with. It can be printed without supports.

The plate has been tested to 280C with only minor glazing of the surface. To go hotter will require a more heat tolerant filament such as PA-CF.

The two mountsThe mounts attach to the effector plate using 2 M3x8mm and 2 M3x2mm screws. Both of these mounts support the heatsink by clamping to the V6 grooved mount using 2 M3x16mm screws. They need to be printed with a filament that is strong and that can repeatedly take threaded screws. This means PLA should be fine, normal PETG probably won't as it's too flexible. For best results, Carbon Fibre filled PLA or even better, CF filled PETG do best.

They do not have to be particularly heat tolerant as they only come into contact with the heatsink at the cold end of the grooved mount. They are also being cooled by the hotend fan.

Tolerances are important when printing these two components. Supports touching build plate are needed for one of the mounts.

As an alternative, Phaetus Dragon mounts have been included to provide a more stable platform for that hotend. Instead of the 3 screws needed, only one is needed to connect the two mounts. The groove mount must be removed from the Dragon hotend so that the 4 connecting screw holes are exposed.

Additional componentsThe effector plate uses a modified fan connector used in: https://www.thingiverse.com/thing:4577330

While fan ducts from the originating connector will fit, they will reach below the height of the nozzle. I've included a couple of fan ducts that can be used with this system.

Separate Fan Ducts are available for the E3D standard hotend and the Volcano hotend configuration.

Hotend cooling fan duct modified from: https://www.thingiverse.com/thing:4572660

Part cooling fan ducts from: https://www.thingiverse.com/thing:4577330 https://www.thingiverse.com/thing:2431261

You can either re-use the magnetic mount for the Z-Probe, or use the included Magnet Holder which will require 2 more M3 thread inserts and 2 more M3x8mm screws. The Volcano Magnet Holder will need an additional 2 M3 thread inserts. If you are reusing the magnetic probe you will need to add the Volcano spacer that is included to clear the nozzle. Using this will require 2 M3x16 screws.

The included magnet holder uses a 20x10x3mm magnet. This needs to be a North pull magnet with countersunk screw holes. This is the one used here: https://www.first4magnets.com/rectangular-c35/20-x-10-x-3mm-thick-x-3-5mm-c-s-n42-neodymium-magnets-4-2kg-pull-p3651#ab_1_1|ps_2_3391

Separate Magnet Holders are available for the E3D standard hotend and the Volcano hotend configuration.

As with the effector, the fan duct and the magnet holder need to be printed from a heat tolerant filament such as ABS, ASA, etc.

ConstructionFor a standard V6 hotend, print: Flsun_Q5_Effector_Plate.stl Flsun_Q5_Effector_V6_Blower_Fan_Mount.stl Flsun_Q5_Effector_V6_Hotend_Fan_Mount.stl Flsun_Q5_Effector_Fan_Connector.stl Flsun_Q5_Effector_Magnet_Holder.stl Flsun_Q5_Effector_Fan_Duct.stl

Substitute where necessary if you want to use a different hotend (i.e. Dragon direct parts, or Volcano parts).

Use appropriate filament as outlined at the top.

For the brass inserts you will need a soldering iron heated up to around 50C below the low point of the filament recommendation. Place the insert on the soldering iron tip and gently press into the appropriate hole (6 on the effector for the arms, 2 on the magnet holder). The inserts should be pushed into the 4mm holes until they are flush. Be very careful after pushing in the inserts, they will be very HOT for several MINUTES afterwards and can easily burn you. Do not twist the inserts as you push them in and be careful to not pull them out as you withdraw the soldering iron.

The order the components are put together matter, so to avoid having to unscrew them multiple times:

-

Screw the part cooling blower fan to the blower fan mount (hole down, fan out).

-

Screw the part cooling blower fan mount to the effector using 2 M3x8mm screws adjacent to the rectangular fan connector hole.

-

Screw the hotend fan to the hotend mount (fan label pointing into the mount).

-

Screw the magnet mount into the effector.

-

Insert the hotend through the effector from the bottom and push onto the blower fan mount.

-

Screw the hotend fan mount to the part cooling blower fan mount using 2 M3x16mm screws.

-

Screw a M3x8mm or shorter screw through the hole in the hotend fan mount onto the grooved hotend mount. Do NOT overtighten this as you will strip the created thread. NOTE: Using this screw is likely to mark the hotend.

-

Screw the hotend cooling fan mount to the effector using 2 M3x12mm screws.

Lastly, there is a zip tie hole on the part cooling blower fan mount to safely attach the cables to.

Printer ConfigurationYou then need to attach the new effector the the printer arms and connect the cables, bowden tube and clip. Once completed the following steps must be performed after switching on the printer:

-

PID tune

-

Delta Calibration

-

Z-Offset

-

Bed Levelling UBL

-

Load filament and print an XYZ cube to make sure it is properly configured

10 x M3 threaded brass inserts (6 x effector arms, 2 x magnet holder, 2 x Volcano magnet holder) 7 x Flat capped M3x8mm screws (2 x blower fan mount, 2 x magnet, 2 x magnet holder, 1 x hotend grub) 2 x Flat capped M3x12mm screws (2 x hotend fan mount) 2 x Flat capped M3x16mm screws (hotend mount) 2 x Button cap M3x12mm screws (hotend fan) 2 x Socket cap M2x8mm screws (part cooling fan)

1 x 4010 24v Axial Fan 1 x 4010 24v Centrifugal (Blower) Fan

1 x 20mmx10mmx3mm North Pull magnet with countersunk screw holes

NotesThe fan ducts and connector will likely need some work to get a good fit with a little sanding or filing to get them to fit comfortably.

If you are building for a Volcano hotend and reusing the stock magnet holder, you will need to print the Flsun_Q5_Effector_v6_Volcano_stock_magnet_spacer.stl so that the Z-offset probe clears the nozzle incase it is hot.

Updates2021-09-26 - Uploaded fixed mounts for: Flsun_Q5_Effector_Dragon_Blower_Fan_Mount.stl Flsun_Q5_Effector_Dragon_Hotend_Fan_Mount.stl

2021-10-11 - Added Volcano magnet spacer if reusing stock magnet holder